How we

do it

We assume a unique position in the value chain, with performance and competence to produce technical and highly demanding parts. The experience combined with technological tools is implemented in all projects and all markets.

Project

Molding

Melting

Finishing

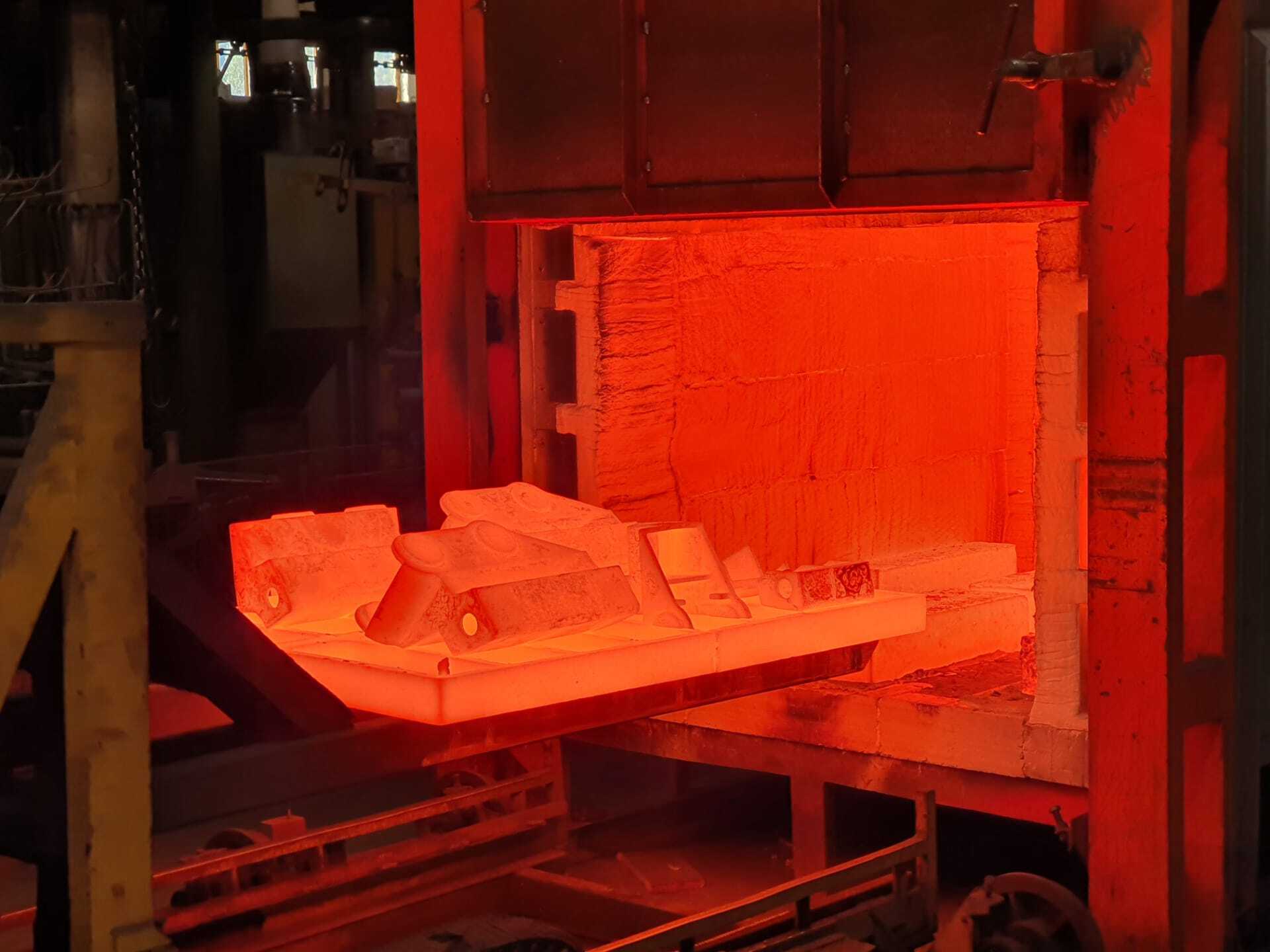

Heat Treatment

Special Operations

Product and Process Quality Control

Inspection and Final Validation

Logistics

Patterns and simulation studies:

3D Drawings

SolidWorks®; Fusion 360®

Dimensional Control

3D FARO® Measuring arm

Filling and solidification simulation

Finite Solutions, Flowcast e Solidcast

Patterns

Traditional patterns

Rapid prototyping

3D printing

Styrofoam

CNC

Rapid prototyping

3D printing

Styrofoam

CNC

Three molding lines in self-drying sand for plate molds and manual molds with a capacity of up to 3000x3000mm.

Cold box process machine with a capacity of 15 L, with the possibility of producing cores in silica sand, chromite sand or additive sand.

Four induction melting furnaces with a production capacity until to 3200kg.

At this stage of the manufacturing process, we invest in the efficiency of operations and training of employees, in order to guarantee the required finishes.

- Three gas furnaces with capacity of 1.3m3, 2.6m3 and 13m3, up to 1200ºC.

- The cooling can be made in air, water, or polymer.

- The furnaces have digital and remote control.

FAL offers a wide variety of solutions and can supply fully finished parts. For this, it can guarantee special operations such as:

- Treatments

- Coatings

- Welding

- Machining

- Painting

- Other required situation

Melting Laboratory

- Chemical analysis through optical emission spectrometry with Fe-base and Ni-base

Metallurgy and Sands Laboratory

- Sand Analysis

- Corrosion Testing

- Flexion Tests

- Metallographic and Micrographic Analysis

Non-Destructive Testing (NDT)

- Visual Inspection

- Magnetic particles inspection

- Penetrant

- Ultrasonic

- Hardness

- Dimensional Control

- Radiographic testing

- Leak test

Destructive Test (DT)

- Tensil test (room temperature)

- Impact test (ambient and low temperatures (until -196ºC)

The requirements are checked at each stage of the production process, in order to ensure conformity throughout the process.

- We guarantee the conformity of our product, according to the customer's requirements/specifications, in all stages of manufacture.

- The finished product is validated through a checklist, which includes all inspections throughout the manufacturing process.

- The conforming product goes into the warehouse for the expedition.

- The Non-conforming Product re-enters the process, for repair or rejection.

- Stock analysis

- Purchase of raw material

- Purchase of subsidiary material

- Entry of products into the warehouse (after final validation)

- FAL ⬄ Subcontracted

- Reception (product, raw material, subsidiary, equipment, and others)

- Packing

- Expedition

Certifications

- ISO 45001 Occupational health and safety management systems (Under implementation)

- ISO 14001 Environmental management systems

- ISO 9001 Quality Management Systems

- EN15085 Welding of railway vehicles and components

- AD-MERKBLATT W0/TRD 100, Directive 2014/68/EU Pressure Equipment Manufacturer

- DB Production for railway vehicles

- ABS Stainless Steel Casting and cast iron casting and steel casting components for marine applications

- DNV.GL Production of cast steel components for marine applications

- Lloyd's Register Marine Production of cast steel components for Ships 4-1 Book D